The Nissan Motor Corporation, in collaboration with its local partners, has commissioned a $9 million assembly plant to produce vehicles in the country.

The Nissan Assembly Plant in the Industrial City, Tema, which has the capacity to produce 11,593 units of vehicles per shift per annum, is a partnership between Japan Motors of Ghana and the Nissan Motor Corporation.

For three shifts at full capacity, the plant can produce 31,666 vehicles annually.

The plant has commenced production with two models, the Nissan Navara and the Peugeot 3008 sports utility vehicle (SUV), which will be produced on contract assemblies.

Yesterday, President Nana Addo Dankwa Akufo-Addo officially commissioned the facility, which has the country’s only vehicle test track.

The track is 419 metres long, with 12 noise detection and vibration sections, alignment checks, steering brakes, clutch concerns, among others.

It also has a water test facility to check for leaks on new vehicles.

The facility is both unique to the country and highly environmentally friendly in its capacity to recycle water, which will be filtered and reused for the water test booth and car wash.

The plant also has two assembly lines and one tester line inside. One assembly line will be used for pick-up trucks and the other for saloon cars and SUVs.

The tester line will be used to test vehicles coming out of the two assembly lines for wheel alignment, brake lights and camera alignment, as well as visual interior and exterior checks.

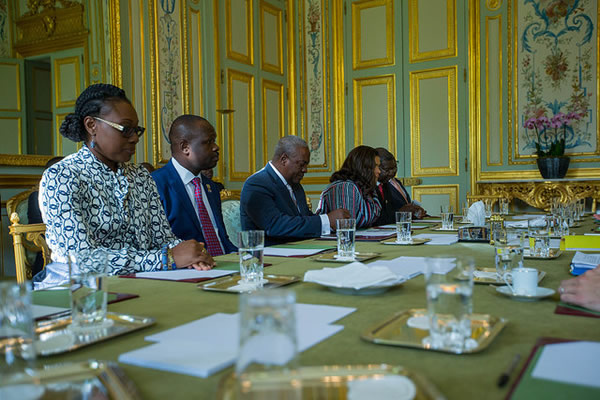

The colourful ceremony to commission the plant, situated on a 22,000 square-metre land in Tema, attracted a number of dignitaries, including the Tema Mankralo, Nii Adjetey Agbo III; the MD of Nissan Africa, Mike Whitfield; the Chairman of the Japan Motors Group of Companies, Jalal Kalmoni, and a section of the Diplomatic Corps.

Vision

President Akufo-Addo, who expressed delight at the opening of the plant, said it was in line with the government’s vision of making Ghana a leading hub in the automobile industry in Africa after countries such as South Africa, Egypt and Morocco.

He explained that the establishment of the assembly plant attested to the attractiveness of the country as a prime investment destination, in spite of the current economic challenges due to the COVID-19.

He indicated that the development of the auto industry was one of the new strategic anchor industries being promoted by the government, under its industrial transformation agenda, to diversify the economy.

High import bill

President Akufo-Addo noted that currently the importation of both motor and transport vehicles constituted the leading value of imports into the country, at an estimated annual value of $1.5 billion.

He said the COVID-19 and its consequent disruption in global supply chain were undoubtedly creating challenges for the country, but they had also opened up opportunities to enhance its industrial productive capacities to feed the domestic market and also export to other markets.

He said it was for that reason that the government had invested resources to enhance the productive capacity of the private sector, particularly the selected strategic sectors of the economy.

“I am delighted that in the automobile sector, we have successfully attracted investments from a number of global iconic brands, including Volkswagen, Toyota and now Nissan.

“Other original equipment manufacturing (OEM) groups, including Hyundai, KIA and ISUZU, have also reached advanced stages in establishing commercial production facilities in Ghana,” he said.

Employment

The President noted that the establishment of assembly plants alone would not create significant employment opportunities expected from the automotive industry.

He explained that it was for that reason that the Ministry of Trade and Industry had laid out a comprehensive component supplier and development programme to support the local production of components for the automotive industry.

He added that in the light of that, the government had developed the integrated bauxite and integrated iron and steel industries to produce the required raw materials that would feed the components manufacturing industry in the country.

In addition, he said, a comprehensive components manufacturing policy was being developed to provide incentives to attract various investors to manufacture components and parts domestically.

Local industry

President Akufo-Addo noted that the rolling out of the policy would lead to harnessing the capacities of local value chain actors, particularly technicians, operating at Suame Magazine, Abossey Okai, Kokompe and other hubs across the country to play critical roles in the component manufacturing and supply development programme.

The Minister of Trade and Industry, Alan Kyerematen, for his part, indicated that Ghana’s automotive development policy had become the masterpiece, presenting itself as a template for other sub-Saharan African countries to adopt.

Taking cognisance of the fact that the investor community expected the full implementation of the policy, he said, the ministry was engaging with the Automotive Assemblers Association of Ghana (AAAG), second-hand dealers, the Ministry of Finance and the Ghana Revenue Authority (GRA) to develop a road map for the smooth implementation of outstanding issues.

“The full implementation of the various provisions under the policy is to position Ghana to take advantage of the increasing demand for vehicles in Africa and boost local production of vehicles, and this, we believe, will enhance the export of vehicles to neighbouring countries within ECOWAS and across the continent,” Mr Kyerematen stated.

Licensed Assembler

The Managing Director (MD) of the Japan Motors Group of Companies, Salem Kalmoni, expressed delight at the commissioning of the plant, coming 17 months after the announcement of its intention.

He said Nissan committed to establishing the assembly plant in Ghana in 2018, and in November 2020, announced the selection of Japan Motors, Nissan’s long-standing distributor in the country, as the “licensed assembler”.

“For the past 17 months, there has been a concerted and coordinated race to design, build and equip the assembly plant and train engineers to achieve what you see before you today: a state-of-the-art, fully equipped, semi-knocked down (SKD) vehicle assembly plant which is the most modern in Ghana,” Mr Kalmoni stated.

He said Nissan had ensured that the assembly plant met all the requirements beyond the Ghana Automotive Development Policy and said although it would start with the production of 1,800 units a year, the plant would ramp up production to full capacity in due course in order to increase employment.

Source: Graphic Online