The team first visited the Sewage Systems Ghana Limited (SSGL) at Korle Lagoon where they were shown how Ghana treats its liquid waste into an end product of clear water that can be used for irrigation, washing of cars and aquaculture, as well as the production of compost for organic fertiliser.

The Managing Director of SSGL, Mrs Florence Cobbold, reiterated that SSGL, in collaboration with the Council for Scientific and Industrial Research (CSIR) with support from the European Union, had commissioned a research into the use of the clear water by-product for large-scale irrigation purposes.

“We are expecting results from the research in 2024, so for now we use most of the recycled water within the plant,” she emphasised.

“We are also leveraging the research to create and improve the acceptance of liquid waste-recycled products in Ghana,” she added.

Untreated liquid

She noted that Ghana, before the advent of the company, was discharging its untreated liquid waste into the sea.

That, she said, posed a lot of environmental challenges, especially for the people living around the Korle Lagoon and its environs.

“But the plant has enhanced a cleaner, healthier and odour-free environment for the people within the community,” she noted.

The plant has a design capacity of 3000m3/day with an average of 300 trucks visiting the plant daily.

The plant has an ISO-certified well-equipped laboratory to ensure that its activities were well within the standards set by the Environmental Protection Agency (EPA) and the Ghana Standards Authority (GSA).

Since its establishment, SSGL has built additional faecal treatment plants at Kotoku and rehabilitated the Mudor Sewerage Treatment Plant, also in Accra.

The team later visited the Accra Compost and Recycling Plant (ACARP).

The Plant Manager, Malik Kwabla Ganyo, who welcomed the team, explained that the plant was an integrated waste processing and recycling company established to receive and process solid waste and produce organic manure for agronomic purposes in Ghana and the West African sub-region.

He added that the plant also addressed the problem of plastic waste through sorting, processing and recycling of such waste.

“We produce high quality pelletised plastics as raw materials to feed local industries for further production into various plastic items.”

He said other recovered materials such as textiles, packaging materials and other highly combustible materials were used to manufacture high calorific burning material/fuels (refuse derived fuels) for specific industries that required such energy for their operations.

Speaking in an interview, the Plant Manager noted that: “We understand that in Botswana little is done with regard to waste treatment, but our value proposition to them is that we need to do some form of recovery on the value chain, as well as valurise the specific streams of their waste to extend the life-span of their landfills.”

Process

“We can process their plastic waste into pellets to feed industry and also process their solid waste into organic fertiliser to improve agriculture,” he emphasised.

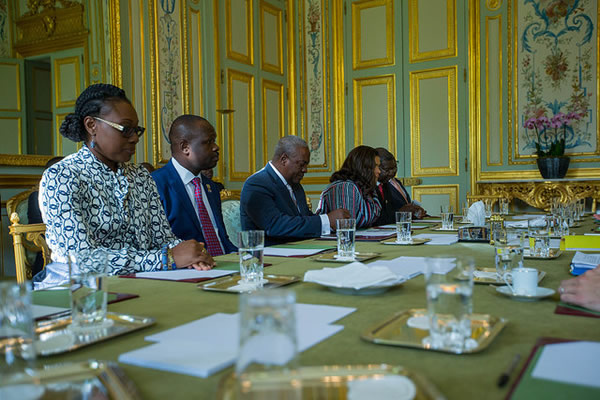

Madam Serame, in an interview after the tour of the two facilities, was impressed with how the two subsidiary companies of the Jospong Group were helping to manage Ghana’s liquid and solid waste.

She admitted there was a lot of potential for the company to invest in other countries, especially in southern Africa where they were also experiencing challenges with waste management.

“I came to see what they do so we can learn firsthand and what may be required for them to set up in Botswana,” she revealed.

“We have an issue of waste management that needs to be addressed, while at the same time make returns from it,” she stated.

“Also, the growth of the company over the years is very impressive and it is very commendable to see Ghanaians at the management level,” she commended the Group.

Private partnerships

She stated that as a country, Botswana was looking for private partnerships, especially with companies that had done it before so they could partner them in various sectors of the economy.

The Chief Corporate Communications Officer for the Jospong Group, Madam Sophia Kudjordji, noted that the Group had been looking for opportunities to support other African countries with their waste management interventions.

“We believe that being the biggest in the sub-region we have what it takes; we have built capacities to be able to impact other countries, that’s why we invited them to see what the Group has to offer.

“We are more into the circular economy where we have gone beyond just the disposal of waste but we recycle and add value to waste and we want other African countries to appreciate,” she emphasised.

The group is currently in Angola, Zambia, Togo, Sierra Leone, among other countries.

Source: graphic.com.gh